5 Key Factors for Micro Flex Circuit Success

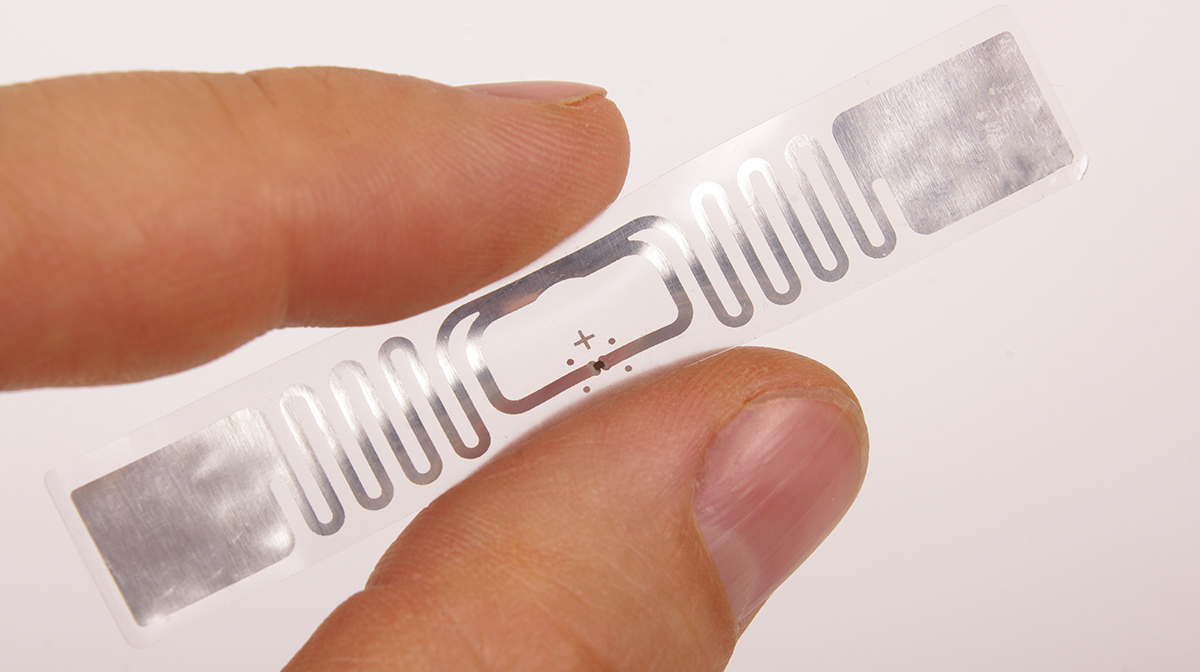

Ultra miniature flexible circuits are highly complex devices with some amazing characteristics. We make circuits with feature sizes ranging from 3 to 10 microns, some of which are so flexible they can wrap around a pencil. Some of our ultra miniature flex circuits have as many as 6 layers (although 6 is not our limit), some can withstand extreme mechanical loads, and some can perform without fault for years in such adverse and critical environments, such as human body implants.

These circuits meet a wide variety of performance requirements; however, a flex circuit that meets one application’s particular requirements, likely will not meet the requirements of another. Each application is different, so the circuit must be different too, and so must be its manufacturing process.

How well your flex circuit meets its performance requirements depends on 5 key factors:

Early Collaboration with Your Manufacturing Partner

Consulting with your manufacturing partner early in the product design cycle is the single best way to ensure a successful ultra miniature flex circuit. That’s because many of the decisions that most impact circuit performance actually occur well-before the product design arrives at the manufacturer’s doorstep. Product and process decisions are strongly interdependent. In particular, your partner will want to discuss the two next factors that help determine success: the circuits design characteristics and its mechanical and environmental requirements.

Circuit Design Characteristics

Every ultra miniature circuit, either rigid or flex, presents significant fabrication challenges. These may include how to achieve the needed line (or trace) density, the target line width and height, the number of layers required, and the number and proximity of various features, such as coils and vias. Where features are located on the board may strongly impact performance factors, such as the circuit’s flexibility, its electrical impedance, and whether features can be fabricated as part of the imaging process or have to be cut out with a laser as a separate step, increases manufacturing cost, complexity and potentially risk.

Another factor in the design, and one that can also significantly impact cost, is the size and shape of the part (which affect how many devices can be nested on a single sheet of materials during fabrication before the sheets are then cut into individual devices.) Smaller and more symmetrical parts will nest better than larger odd-shaped parts, so unit costs will therefore also be lower.

Collaborating early in the design cycle with your manufacturing partner allows you to make design choices that enhance manufacturability as well the likelihood of meeting other challenges, like those discussed next.

Mechanical and Environmental Challenges

Designing a circuit that can be made with modern fabrication technology is one thing. Designing a circuit that can withstand the application’s mechanical and environmental challenges is another.

Among the challenges that should be discussed early with your fabrication partner are:

- How much will the circuit have to bend?

- How much tension will be applied in the application?

- How much shock and vibration must the circuit withstand?

- What about acceleration loads?

- Is the circuit subject to high humidity?

- What about contact with liquids?

These challenges must be taken into account when deciding how to deal with the design factors discussed, like line density and number of board layers, as well as more process-oriented decisions like which fabrication materials and process steps to use.

Quality of Manufacturing Facilities

Of course, the best design plans also require the best plant and equipment in order to carry out those plans. That includes state-of-the-art:

- CAD systems

- Photolithography masking and imaging

- Metal sputtering and plating (at an almost-atomic level)

- Advanced laser cutting

- Ultra pure manufacturing equipment and clean rooms

What’s even more important is the ability to operate this equipment to get the best results, which brings up the final key success factor:

Flex Micro Circuit Manufacturing Experience

Fabrication at this microscopic level often takes place on the edge of what is possible. Knowing how to take an extreme set of requirements and translate them into a production run that is both routine and cost effective takes highly specialized skills and years of experience, especially if one of the requirements is to meet a tight turnaround schedule driven by a fleeting market opportunity. In fact, that’s probably the best reason of all to collaborate early with your circuit fabrication partner — to win in your market.

Do you have a significant micro flex circuit market opportunity or an extreme set of fabrication requirements? Talk to us. We’ll be happy to help you come up with a manufacturing solution that meets all your criteria for success!