Acquisition Further Positions Cirtec as a Leading Vertically Integrated Provider of Design and Contract Manufacturing Services for Complex Medical Devices Cirtec Medical Corporation, a strategic outsourcing partner for complex medical devices [...] Read More

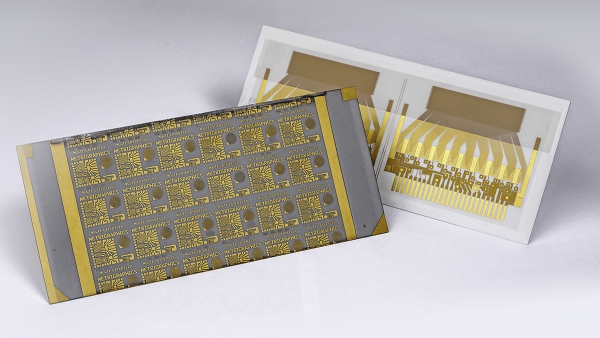

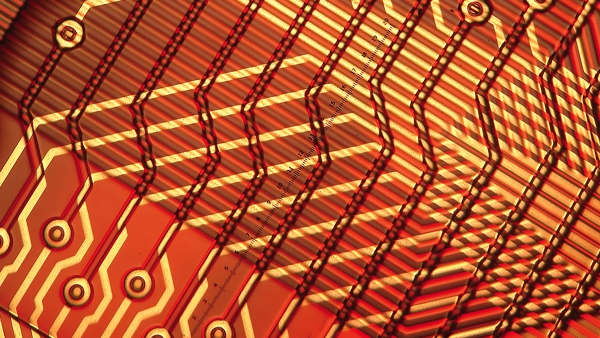

Our thin film process is a fundamental technology uniquely suited to the task of making miniature/micro circuits for medical sensor and RF applications with extremely small and uniform features that have extremely consistent electrical performance [...] Read More

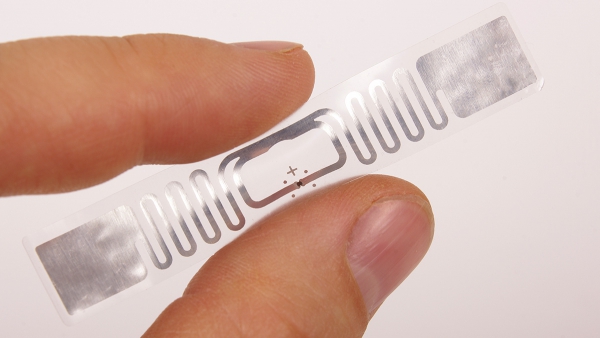

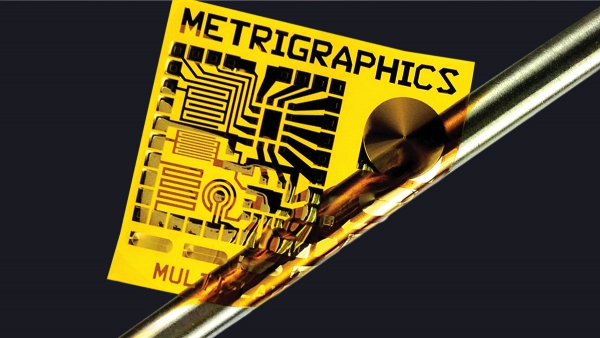

Of all the devices our clients call on us to make, ultra-miniature flex circuits are among the most challenging. Success often requires spending considerable upfront time with customers to gain a full understanding of their specific requirements as well [...] Read More

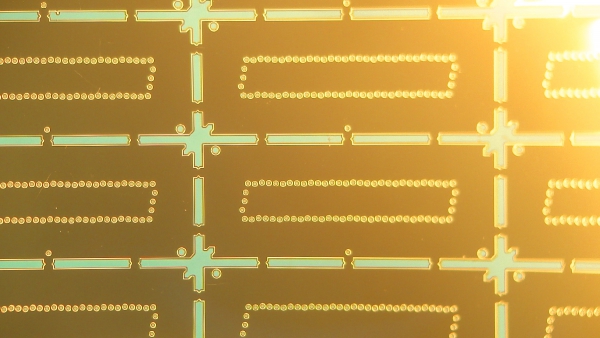

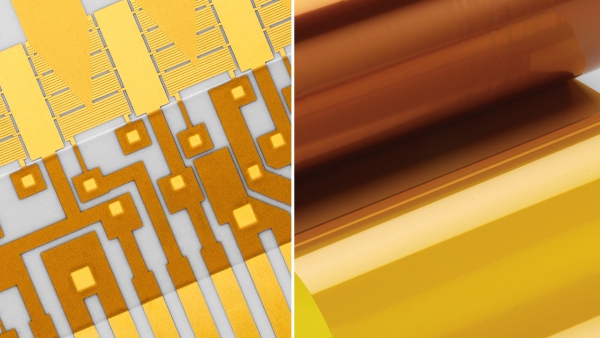

Sputtering and photolithography vs. chemical etching—the advantages are clear. Device makers have a choice of whether to specify an additive or subtractive process for fabricating the micron-scale circuits used in their products. Knowing the [...] Read More

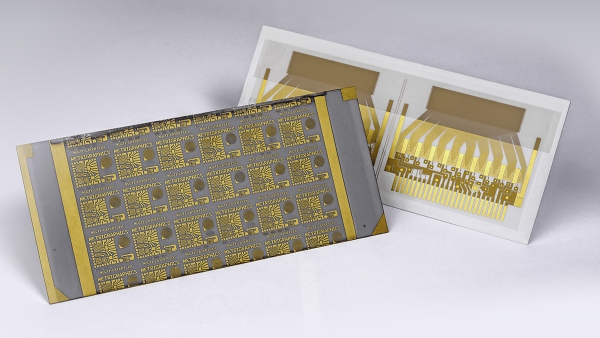

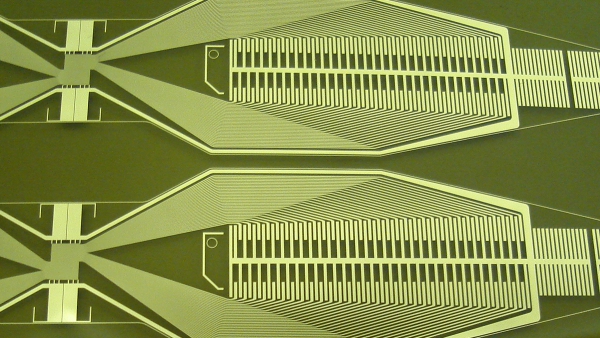

Ultra miniature flexible circuits are highly complex devices with some amazing characteristics. We make circuits with feature sizes ranging from 3 to 10 microns, some of which are so flexible they can wrap around a pencil. Some of our ultra miniature [...] Read More

Medical design is increasingly impacting miniaturization. Testament to this, as a micron-scale process developer and manufacturer, we’re receiving more and more requests from biosensor and device designers looking to push the limits. Circuits now [...] Read More

In an earlier blog post we discussed why micron-scale circuits tend to perform better when made using an additive versus a subtractive process. The additive process defines circuit lines by adding (electroplating) conductive material on top [...] Read More

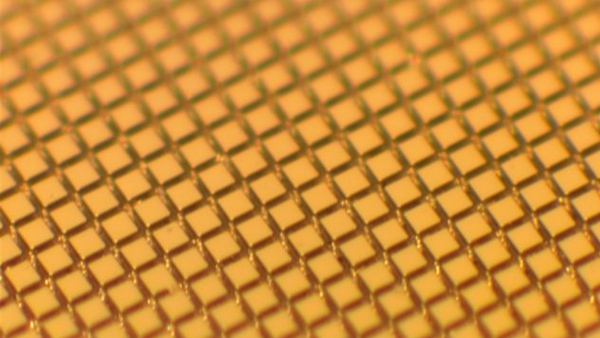

Does your product or application call for a very tiny part? If so, nano-scale electroforming may be your best or even your only option. To find out for sure you’ll need to talk to someone with expertise and experience in this highly specialized [...] Read More

Are you looking for a reliable photolithography partner? Our proprietary photolithography process ensures that you get more consistent trace definition, thinner and therefore more flexible circuits (where needed) AND more uniform circuit lines (i.e., [...] Read More

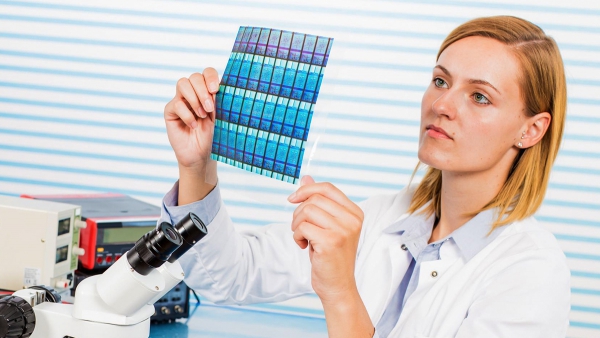

Thin-film circuits can be applied to flexible polyimide substrates making them capable of being bent and shaped considerably without impact on circuit performance or reliability. As such, the combination of flexible material and thin-film circuit geometries [...] Read More

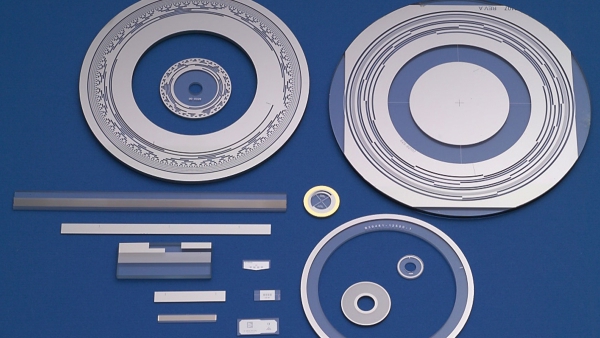

For more than 50 years we've been a trusted supplier of precise optical components for motion control, analytical instrumentation, test and other optics markets — all designed and manufactured to impossibly high standards of precision and reliability. We [...] Read More

Giving Our Customers What They Want Our customers have very high standards when it comes to selecting the source of their electroformed parts. They look for extreme capabilities in areas like: • Feature size • Feature controllability • [...] Read More

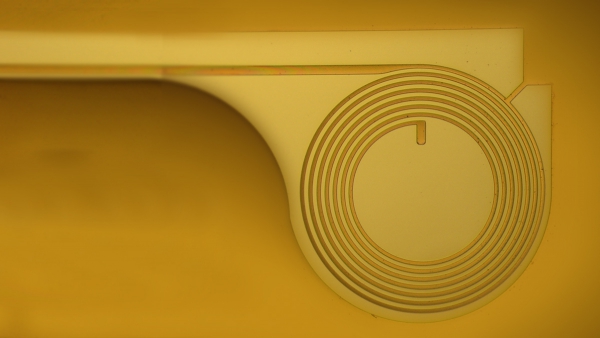

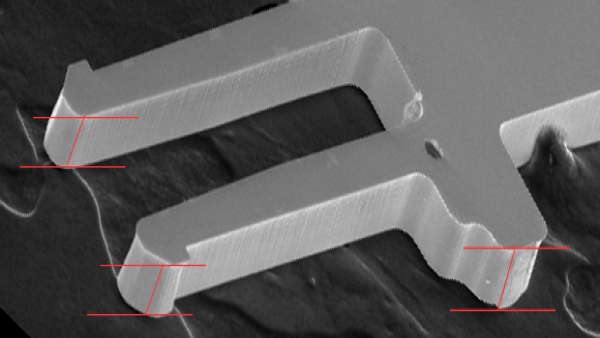

Precision electroforming is an additive process in which 2-D and 3-D microstructures are formed by electrochemically depositing metal into a precisely formed photoresist mold. Electroforming is ideal for fabricating micron-scale, metallic components as [...] Read More

When that call comes in there are only a few companies in the world who can handle it. In fact, these circuits often have feature sizes ranging from three to ten microns and can consist of six or more layers. We call them ultra-miniature [...] Read More

Though a medical device designer may be an expert in the specific application and sensing technology employed in a device, this expertise does not necessarily translate to building that technology on a large scale with stringent reliability constraints. [...] Read More

Though a device designer may be an expert in knowing the specific technology needed in a device, this expertise does not necessarily translate into knowing how to design and produce the necessary circuitry for the size, reliability, and mass production [...] Read More

While many factors will enter a decision, on the basis of pure precision, electroforming excels. Additional advantages include layering options (electroformed metal can be molecularly bonded together) and the ability to introduce different substrate materials [...] Read More

The ultimate factor in deciding when not to use the Kapton polyimide film manufacturing method is a combination of desired size and flexibility. Basically, the moment you’re uttering “micron” as opposed to “mils”, best to [...] Read More

Electroforming, electrochemical machining, and electrical discharge machining all use electrolytic baths. But only one is additive, which helps explain why it’s also more precise. Electrolytic baths have a long history as a way to add [...] Read More

Our micron-scale flexible circuits can be produced in multi-layers and with circuit lines as narrow as 3 microns. They’re flexible enough to wrap around small objects and are durable enough for harsh MIL-COM environments. Circuits are achieved [...] Read More

We have recently announced our move to Lowell, MA. This move provides additional space to accommodate company growth and allow for greater advances in the manufacturing of their customers products. The greatest benefits lie in the addition of the [...] Read More

We have launched our advanced 3D electroforming services. These services are an ideal solution for OEMs looking to integrate complex multilevel structures manufactured at an almost atomic level of precision — and who also require high repeatability [...] Read More

We now routinely achieve one-micron resolution in our photolithography service. We can provide these services to customers looking to fabricate ultra-miniature rigid and flexible circuits, ultra-miniature electroformed structures, and high-precision [...] Read More

We have achieved breakthrough performances on key competitive benchmarks in the fabrication of precision optical components. These benchmarks include range of products, range of technologies, feature definition (e.g., edge definition and line-width tolerance), [...] Read More

We have developed an advanced process for applying metal layers to circuit substrates and to polyimide layers on multilayer circuits. The process works for both rigid and flexible circuits. The new process achieves superior results based on a number [...] Read More

We have developed new breakthroughs in processing substrate-based ultra-miniaturized circuits. The additive processes used are an alternative to traditional chemical etching, which causes circuit lines to slope, resulting in performance variations and [...] Read More

We have achieved large-scale production of micron-scale flexible circuits six or more layers high with traces (circuit lines) as narrow as 3 microns (11.81x10-5 inches). The circuits are so flexible they can be wrapped around objects with diameters as [...] Read More

Announcing our capability to develop Extreme Resolution Micro Flex (ERMF) Circuits for medical sensor applications, including various in body and fluid sensors. Using additive photolithographic processes, ERMF circuits can be manufactured [...] Read More

We have developed an advanced process for creating high aspect ratio three-dimensional microstructures. Precision electroforming can create three-dimensional, single or complex, multi-layer microstructures. Geometric options are unlimited because the [...] Read More

.jpg)

.jpg)