Flexible Microcircuits for RF/microwave and Medical Biosensor Applications

Our company is uniquely positioned to meet the needs of today's RF/Microwave manufacturer and medical biosensor OEM who is looking to break through the boundaries of what a typical flex circuit can do.

From prototyping to volume manufacturing, we offer full lifecycle flex circuit and non-flex circuit production capabilities that include:

- Circuit lines and spaces as small as 3 microns

- Vias as small as 25 microns in diameter

- Substrates laser cut to any shape, including through-hole geometry

- Plated through holes (PTHs) to ground with "metal-backed" ceramics

- Multi-layer devices with up to six metal layers

- Solder masks (metal or polyimide)

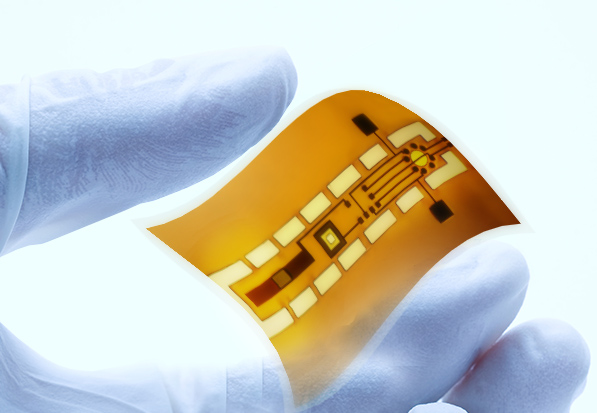

Using additive photolithographic processes, extreme-resolution, micro flex circuits can be manufactured. For some designs we can achieve traces as narrow as three microns. These flex circuits can also be delivered in complex, high-resolution shapes and patterns. These microcircuits are produced with very thin layers of sputtered metal, or thicker-plated metal such as gold or copper, on Polyimide substrates.

Using electroforming, photolithography and proprietary technology, we make a wide variety of ultra-miniature microelectronic flex circuits that achieve product-design goals not possible any other way.

Flexible microcircuit products include:

- Single-layer flex circuit

- Multi-layer flex circuit

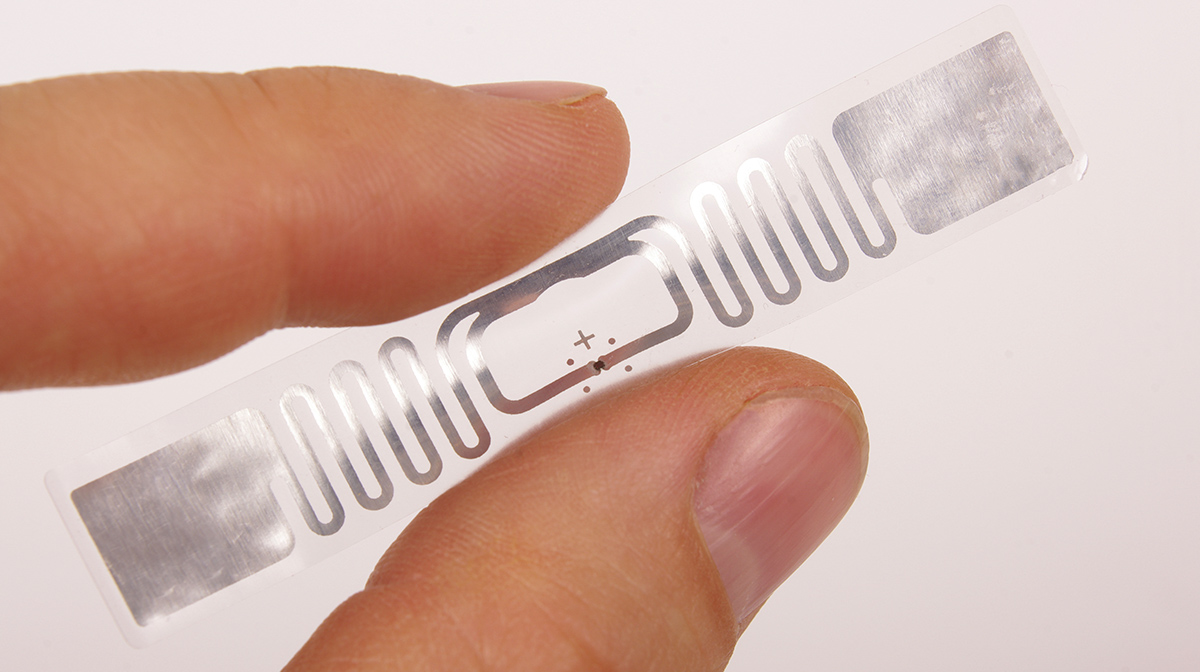

- Coils

- Sensor components

- Electrodes (neuro-stimulation)

Applications for single-layer microcircuits include invasive medical devices and in-vitro diagnostics, and other biosensors. Multi-layer flex circuits (up to six or more layers) include additional conductive layers that are independently stacked, aligned and interconnected. Plated conductive vias connecting the different layers are often required. Applications for these circuits often include small RF/microwave antennas and high vibration environment circuits. Contact us for expert manufacturing of your flex circuit and non-flex circuit requirements.