We are Ready to Assist on Your Latest Project

We are the proven source for ultra-miniature component design and high-volume manufacturing ranging from electroforming, thick and thin-film sputtering & coating, ion beam etching, designing, machining and milling. We serve medical, biotechnology, OEM, telecommunications and semiconductor industries. Whether you’re searching for custom fabrication of ultra-high precision components or specific products we’re happy to assist you. Fill out your information above and get the conversation started today.

Frequently Asked Questions

Among the challenges that should be discussed early with your fabrication partner are:

- How much will the circuit have to bend?

- How much tension will be applied in the application?

- How much shock and vibration must the circuit withstand?

- What about acceleration loads?

- Is the circuit subject to high humidity?

- What about contact with liquids?

These challenges must be taken into account when deciding how to deal with design factors — like line density and number of board layers — as well as more process-oriented decisions like which fabrication materials and process steps to use.

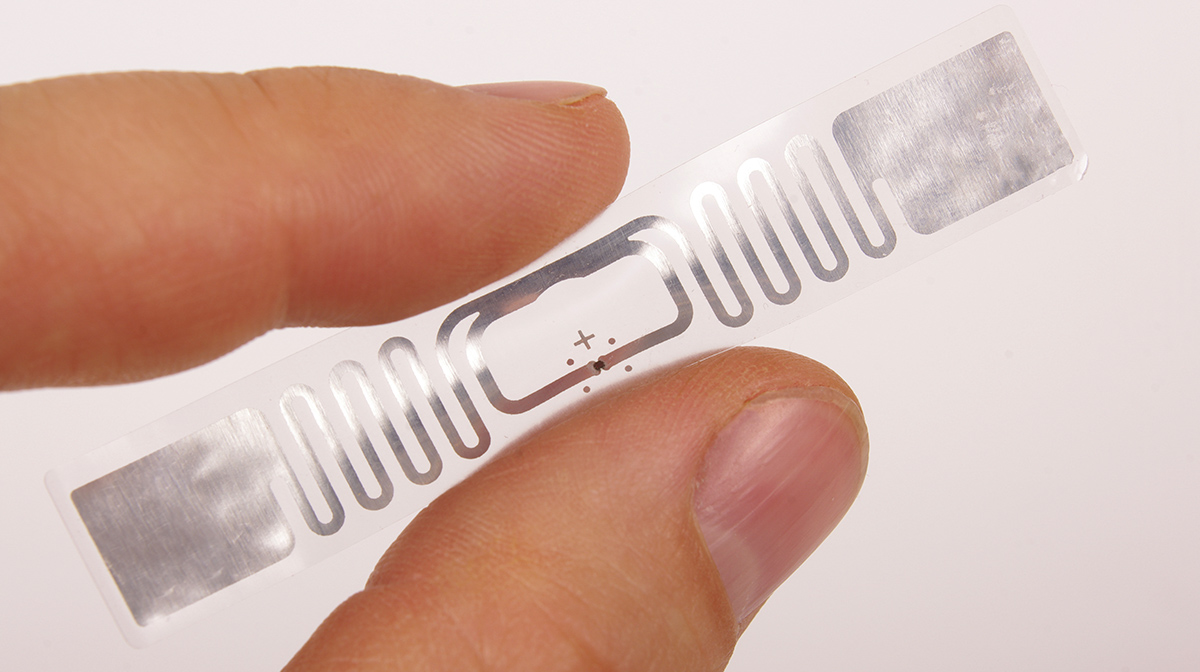

Both methods are used to create circuit lines on a surface. A subtractive technology creates circuit lines by subtracting or removing material — in this case, metal from a surface pre-bonded to a non-metallic polyimide base. An additive process creates circuit lines by sputtering a positively charged metal to a negatively charged base. A large part of what gives additive processing all the advantages listed above is photolithography lines will be more precisely defined, have greater resolution and line uniformity; meaning greater component reliability, especially at much smaller scale.

5 Key Factors for Micro Flex Circuit Success

Ultra miniature flexible circuits are highly complex devices with some amazing characteristics. We make circuits with feature sizes ranging from 3...