Low-cost, High-quality Electroforming With Utmost Repeatability and Precision

Complex multilevel electroformed structures are a specialty at our company. This additive process is completed by electrochemically depositing metal into a precisely formed photo-resist mold. Electroforming is ideal for fabricating micron-scale metallic components as well as for making injection molds used for forming nonmetallic microstructures with nano-scale features. Benefits include low-cost, high-quality production plus high repeatability.

With our precision electroforming expertise we can create three-dimensional, single or complex, multi-layer microstructures. Geometric options are unlimited because the X, Y, Z structural plane of each layer is formed by the photoresist image. These structures may be freestanding or connected to comb-like supports to facilitate handling or fixture mounting.

Sample electroformed component applications:

|

Commonly used materials:

|

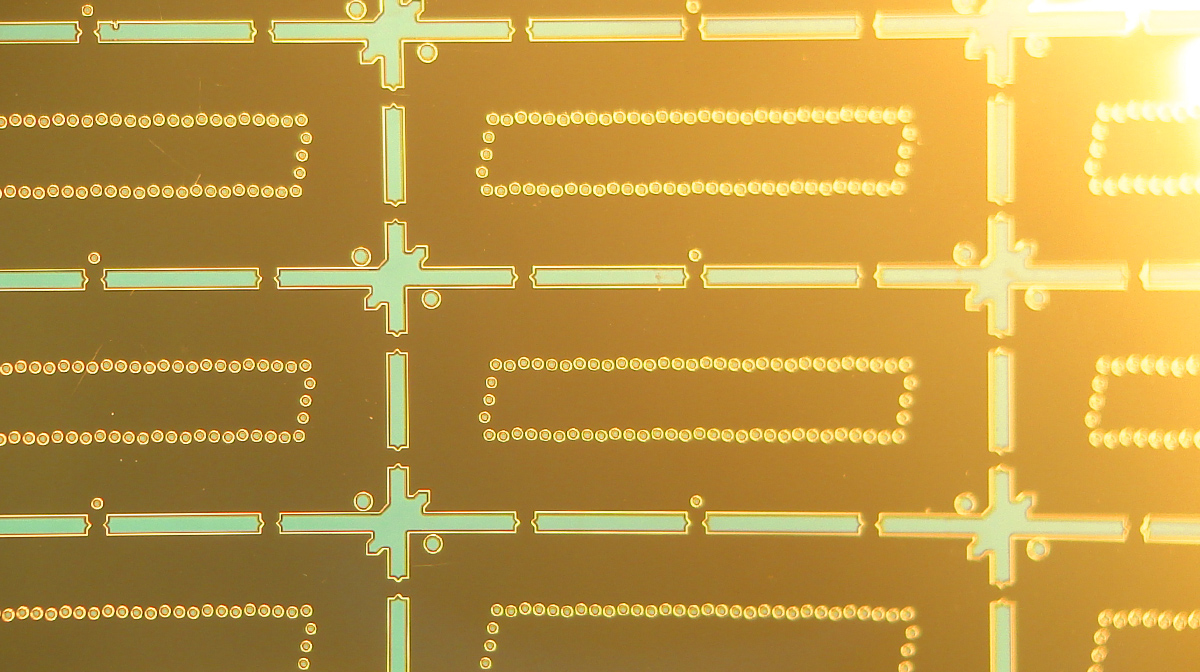

Micro Screen and Micro Mesh

We use our precision-electroforming capabilities to create micro screen with square or round apertures, with bar widths as small as 0.010 mm. We can array the apertures in a wide range of formats - hexagonal, rectangular or whatever your application requires. Medical applications include inhalant atomizers, while micro mesh is also used in such electronic applications as RF shielding and imaging screens.

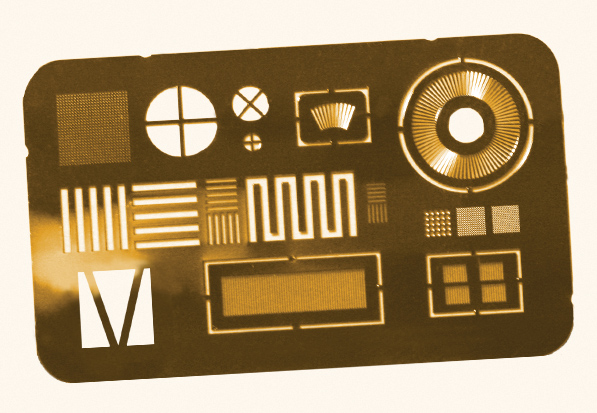

Encoder Disks

Motion-control device manufacturers around the world rely on our precision-electroformed encoder disks and scales. We can manufacture encoder disks with total pitch values (line + space) as small as 0.025 mm. These values equate to 40 lines per mm or 1,000 lines per inch. We can also create lightweight, robust, air-gap aperture scales.

Encoder applications include optical-rotary and linear encoding systems. Precision-electroformed disks are also preferred in applications where index of refraction, fragility and weight are issues.

Embossing Tools

We apply the micron-level precision afforded by our electroforming process to manufacture extremely precise embossing-tool master plates. Highly durable embossing molds with highly complex patterns may be electroformed using nickel cobalt, which has extremely fine grain, very low stress, and a hardness in the Vickers 500 range. We also use precision electroforming to create casting master molds for PDMS or similar materials.

Contact us for expert manufacturing of your electroformed components.